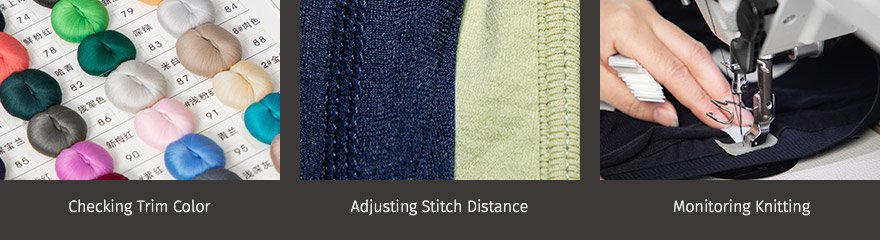

Knitting

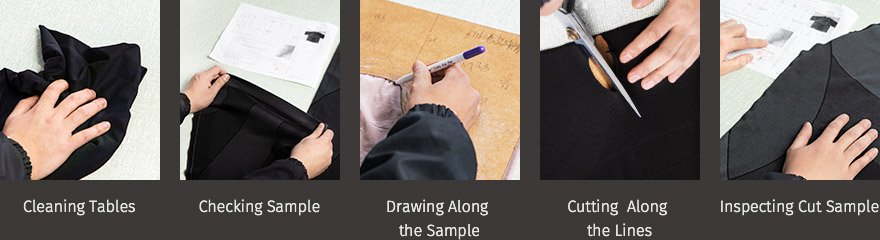

Knitting begins only after the pre-production sample is fully approved. Before production, we conduct:

① Raw material and yarn threading confirmation;

② Verification of technical specifications and measurements;

③ Inspection of fabric surface and texture quality.

Throughout knitting, our quality inspector monitors output every 2 hours to ensure consistency, accuracy, and fabric integrity from start to finish.